COSCO Kansai introduces new technology for anti-corrosion construction of nut CUP

HC Surface Treatment Network News: Recently, COSCO Kansai Paints has introduced a new high-efficiency anti-rust technology from Japan - a new technology for anti-corrosion construction of nut CUP. The CUP injection method is to coat the thick joints of the weak joints (bolts, nuts, screws, and rivets) of the steel bridge with a good coating method to pay for the long-term corrosion resistance. COSCO Kansai introduces new technology for anti-corrosion construction of nut CUP When installing large steel bridges, the rods are usually assembled into an enlarged unit on the ground, which can reduce the workload of high-altitude installation. The way in which the members are assembled includes the welding method and the bolting method. The bolting method uses high-strength bolts to connect the rods. If the bolt is exposed to the natural environment such as humid air or rain for a long time, the corrosive medium in the external environment invades the screw, and the small defect at the thread cracks under the action of stress corrosion and corrosion fatigue. Once the mechanical properties of the bolt are lowered, the bridge will be The safe use of this brings huge hidden dangers. Therefore, after all the bolts are tightened, the bolt joints must be coated with anti-corrosion coating to avoid the original design strength of the bolts due to corrosion. Due to the large number of edges at the bottom of the bolt and nut, the conventional coating method is prone to defects such as leakage coating and uneven coating film, and the integrity of the coating film cannot be ensured. The newly introduced CUP injection method is a new breakthrough in the anti-corrosion technology of bridge bolts. With the patented injection cup, the coating thickness of the bolt can reach 1000 microns or more, as if the bolts are put on a thick "armor". In order to achieve long-term anti-corrosion effect, the bridge maintenance period is also greatly extended, and the labor cost and material cost of maintenance are effectively reduced.

Material: SS304, SS316

Weave type: Plain weave, Twilled weave, Dutch weave

Features: Corrosion-resisting, Wear-resisting

Uses:Mainly used for filtering and sieving, extensively used in petroleum, chemical industry, enviroment protection,

mine, airspace, paper-making, electronic, metallurgy etc.

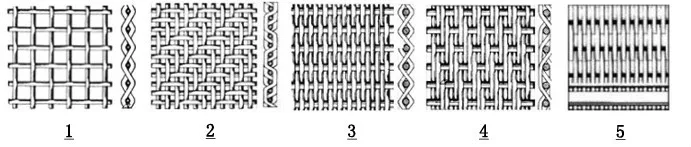

Weave type explanation

1. Plain Weave: also called tabby weave, linen weav or taffeta weave, is the most basic type of weaves.

In plain weave, the warp and weft are aligned so they form a simple criss-cross pattern. Each weft thread

crosses the warp threads by going over one, then under the next, and so on. The next weft thread goes under

the warp threads that its neighbor went over, and vice versa.

to the right or left, forming a distinct diagonal line. This diagonal line is also known as a wale. A float is the portion of

a yarn that crosses over two or more yarns from the opposite direction. Stainless Steel Series,Stainless Steel Wire Mesh,Stainless Steel Crimped Wire Mesh,Stainless Steel Window Screen Anping Shengjia Hardware Mesh Co.,LTD , https://www.oilshaleshakerscreen.com

2. Twill Weave: In a twill weave, each weft or filling yarn floats across the warp yarns in a progression of interlaces

3. Plain Dutch Weave: similar with plain weave, just the weft and warp wire have different wire diameter and different mesh size.

4. Twill Dutch Weave: similar with twill weave, just the weft and warp wire have different wire diameter and different mesh size.

5. Reversed Dutch Weave: difference from standard Dutch weave lies in the thicker warp wires and less weft wires